Project References

Cocaine Disposal

01. Overview

In January 2018 INSEE Ecocycle Lanka (Private) Limited, popularly known as INSEE Ecocycle initiated a program to work on the vital national issue of waste management. As a sustainable waste management solutions provider, INSEE Ecocycle joined hands with several government bodies, namely, the Sri Lanka Police, the Police Narcotics Bureau, the National Dangerous Drugs Control Board, the Government Analyst’s Department and the Presidential Task Force on Drug Prevention to responsibly dispose of Waste Cocaine Hydrochloride through Cement Kiln co-processing for the second time in Sri Lanka.

02. The context and Challenge

- The project background and description

The waste cocaine consisted of material recently confiscated by the Police Narcotics Bureau, verified as narcotic material under the guidance of the Government Analyst’s Department, the National Dangerous Drugs Control Board and Attorney General’s Department. After the recommendation of the Chief Medical Officer of the Colombo Municipal Council advising to safely dispose of the material at a temperature above 1300℃, INSEE Ecocycle joined hands to provide a safe and comprehensive disposal solution for this narcotic material.

- The problem /Challenge

Considering the sensitive nature and the high-security requirement of the narcotic material, ensuring the safe and secure disposal of this material was an enormous challenge.

INSEE Ecocycle performed a technical evaluation on the pre-processing activities and the disposal mechanism of this dangerous drug while minimizing social and environmental impact. This included a comprehensive risk assessment and a mitigation action plan covering the environmental, social, health and safety aspects throughout the pre-processing, logistics and co-processing value chain to ensure safe and secure disposal.

- Objectives and goals

The objective of the initiative was to completely dispose of the confiscated cocaine hydrochloride through co-processing safely and securely with zero harm to society and the environment.

03. The process and solution

There are several types of feeding mechanisms available at the Cement Kiln co-processing facility. The confiscated Cocaine Hydrochloride is co-processed through a liquid feeding channel, which enables closed feeding with minimum exposure to the environment.

The entire process can be divided into three phases, namely, pre-processing of Cocaine, transportation of the pre-processed Cocaine to Puttalam Cement Plant and co-processing of the cocaine in the Cement Kiln as the final solution.

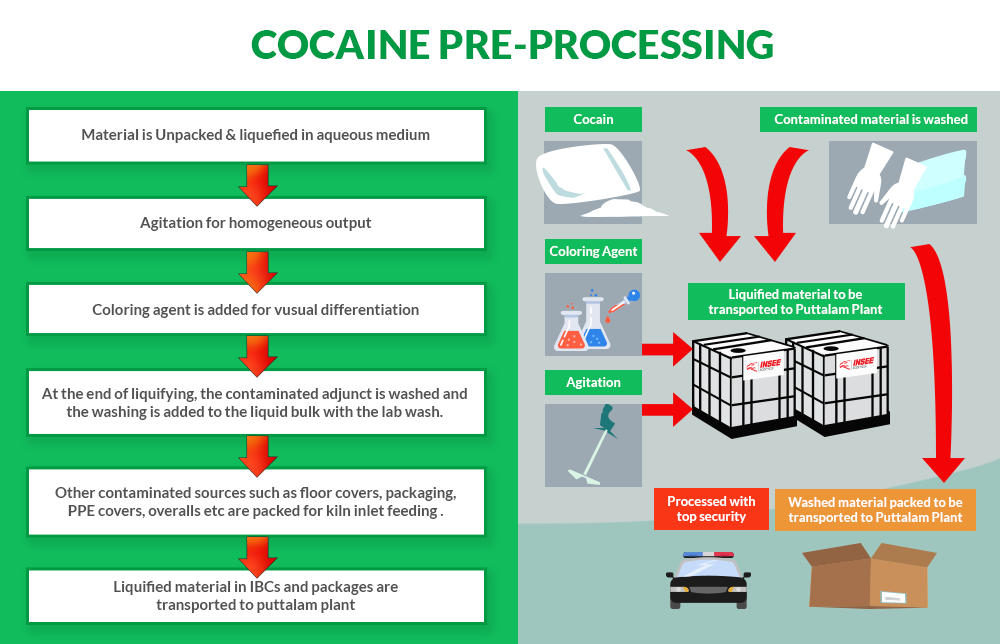

Pre-Processing

The confiscated Cocaine is liquified in an aqueous medium to ensure that this material is completely disposed of through a liquid line rather than through a solid feeding line. The pre-processing involves a conversion of the chemical structure and the physical state of the material. As per the calculated ratios in pre-trials, the material is dissolved in water ensuring zero residual remains. For visual differentiation of the material, a coloring agent is added. Pre-processing is done under high security to prevent re-production of Cocaine through neutralization.

Transportation

The liquified material is then transported to the Puttalam Cement Plant where the second phase of the disposal takes place. Transportation is carried out via intermediate bulk containers using GPS-enabled, specially built hazardous waste transporting vehicles which are especially modified truck fleets with a secondary compartment to manage spillage as proactive emergency preparedness. These fleets carrying the consignments are entrusted to specially trained drivers and assistants and are escorted entirely by the Sri Lanka Police and the Police Narcotics Bureau officials.

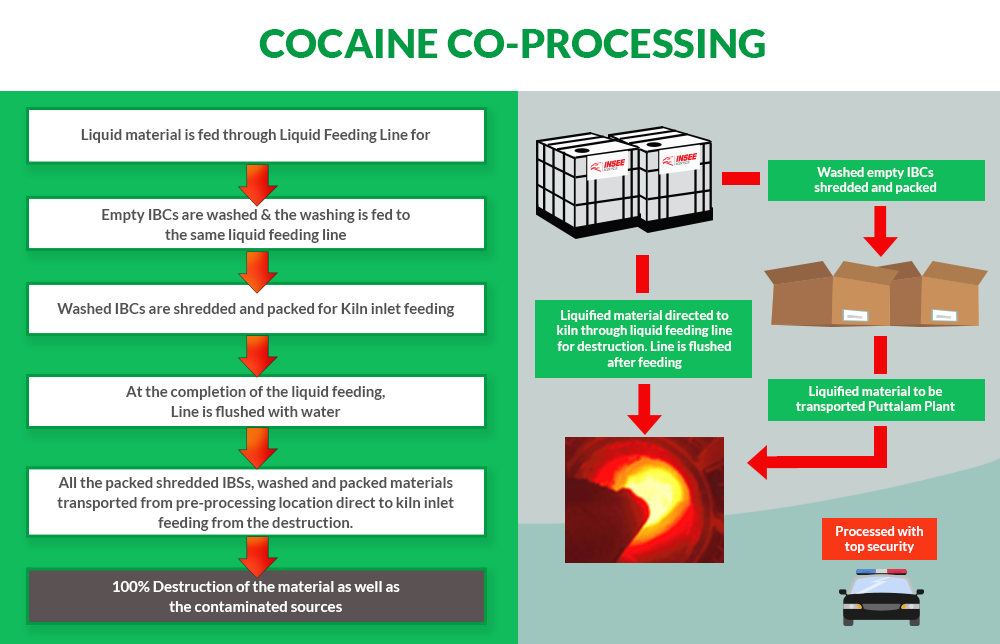

Co-processing

In the third step of the operation, disposal takes place through Cement Kiln Co-processing by using the existing temperature of 1800- 2000℃ with 4 – 6 hours of residence time. Puttalam Cement Kiln is technically proven to have a destruction removal efficiency of 99.999999 %. This ensures zero residual remaining post-disposal of the confiscated Cocaine Hydrochloride. Continuous Emission Monitoring (CEM) is carried out during and after this phase of the final disposal to ensure no harmful emissions are released into the environment.

The company disposed of 928kg and 769 kg of waste Cocaine in January 2018 and April 2019, respectively, using the same technology taking a step forward to resolve the problem.

During this whole process of mixing with water and until the material is fed into the Puttalam cement plant, the material is under a high level of security observation for ensuring its safety.