WHAT IS MEANT BY PRE- AND CO-PROCESSING?

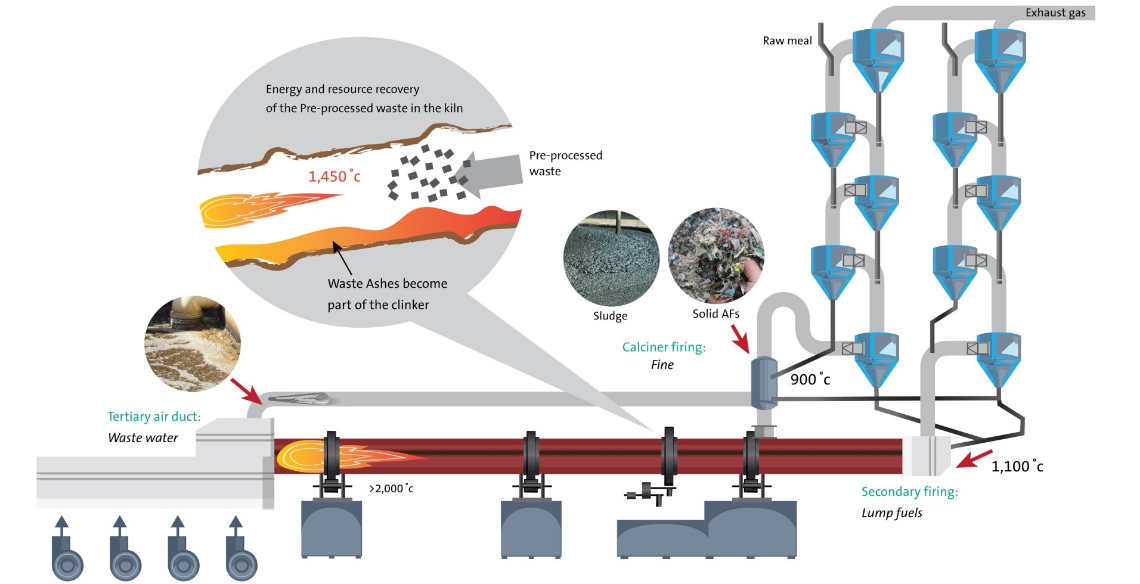

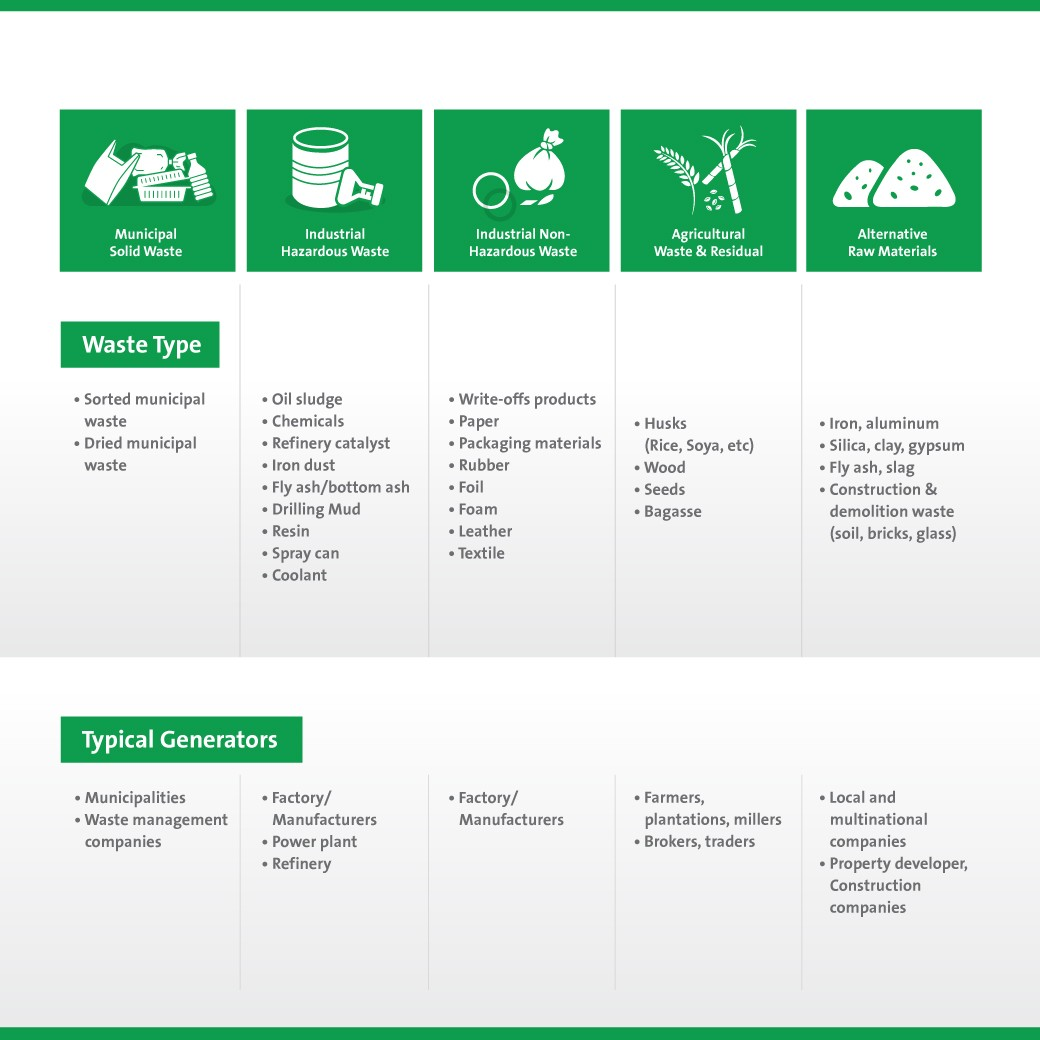

Pre-processing refers to preparing of waste to make it suitable for co-processing in cement kilns. Waste is converted from an unwanted discarded material to a useful resource, so-called AFR.

Co-processing refers to using AFR in the cement production process at suitable feed-in points in a controlled manner, where it burns as fuel and provides raw material. This enables substitution of primary fuels (coal, petroleum coke, natural gas) and raw materials, recovering energy from the waste and recycling its mineral content. Only qualified waste materials may be used for this process.