Feature Stories

Looking at industrial waste management trends in Thailand

Industrial waste management can be a challenge for international companies operating in Thailand. Companies are expected dispose of it within the legal framework set up by the government which makes knowledge of the process invaluable. Current trends in the country are being shaped by both the circular economy and environmental responsibility.

To begin with, it is necessary to have an understanding about what is considered industrial waste. Industrial waste is comprised of any material that has no use after the manufacturing process has been completed. There are many types of industrial waste, but there are two important groupings that relate to disposal–non-hazardous and hazardous.

According to the Department of Industrial Works, there was 16.80 million tons of industrial waste produced in Thailand during 2019, a 24 percent decrease from the previous year. Of this total, 15.46 million tons were non-hazardous while 1.34 million tons were hazardous.

Non-hazardous waste consists of items that do not pose immediate harm to people or the environment. Office products, scrap metals, select textiles and certain types of construction materials among other things are considered to be non-hazardous waste.

Alternatively, hazardous waste is comprised of hazardous substances or anything waste that exhibits hazardous characteristics such as being flammable, corrosive, reactive or toxic. Since it poses a risk to the environment and/or human health, this type of waste has strict regulations in place for both its storage and disposal.

In Thailand, hazardous waste is considered to be any waste that has hazardous constituents, was contaminated with hazardous substance or has hazardous characteristics as prescribed in Annex 2 of the Notification of Ministry of Industry: Industrial Waste Management and Disposal, B.E.2548 (2005).

Regardless of type, industrial waste management is a necessary component of the day-to-day operations for manufacturing firms in Thailand. There is a legal framework in place for the handling of both non-hazardous and hazardous waste which covers everything from production to disposal or recovery.

Companies operating in the Kingdom are bound by law to be compliant to all waste management laws. Additionally, firms must know if their waste is classified as non-hazardous and hazardous and keep each type separate.

Since hazardous wastes poses a greater risk to the environment and human health, there are more stringent regulations in place regarding its storage and disposal. However, non-hazardous waste also has a set of directives that stipulate it how it is recorded and transferred.

Understanding industrial waste management regulations in Thailand

Industrial waste in Thailand is regulated by the Department of Industrial Works (DIW) and the Ministry of Industry. As it relates to the industrial waste disposal process, the DIW has identified three key stakeholders who each assume liability at various points.

The first stakeholder classification is the waste generator. This is the factory that generates and stores waste on-site. The second stakeholder classification is the waste collector and transporter. This is the organization responsible for the transportation and/or storage of waste to a disposal site. Finally, there is the waste processor, the organization carrying out the waste disposal process.

In terms of industrial waste management regulations, all factories operating in Thailand are obliged to follow the Factory Act B.E. 2535 as well as the latest announcements of the Factory Act (No. 2 and No. 3) B.E. 2562 (2019). Meanwhile, the Notification of Ministry of Industry: Industrial Waste Management and Disposal, B.E.2548 (2005) provides the framework for how factories can dispose of waste.

Factories operating in an industrial estate are also legally obligated to follow all Industrial Estate Authority of Thailand (IEAT) notifications. The one that relates to waste disposal procedures is Notification of IEAT No.79/2554 Re: Implementation processes of Solid Waste Management and Industrial Waste in Industrial Estate, B.E. 2554 (2011).

This notification includes detailed reporting guidelines along with other important guidance that factories in Thailand’s industrial estates will need to be familiar with. More information can be found in the IEAT handbook.

Environmental responsibility and industrial waste management

Legal compliance is simply one aspect of industrial waste management. Businesses should also be mindful of their environmental responsibility. Ultimately, successful waste management not only ensures you are following the law, but it reduces the risk of polluting as well.

Environmental responsibility doesn’t have to impede business. A comprehensive industrial waste management plan allows companies to act divisively when it comes to protecting the environment while not being a burden to operations.

It is important to note that poor industrial waste management can create environmental issues regardless of industry or waste produced. An example of this in Thailand is plastic waste. Currently, most plastics are considered to be non-hazardous waste. Even so, improper disposal can lead to leakage where harmful materials end up damaging ecosystems.

However, the harm hazardous waste can have on the environment can be much more immediate. Take items such as batteries or other electronic waste. Improper disposal of these can create water and air pollution that harms the local community while being easy to trace back to its original source.

At the end of the day, failing to comply with industrial waste management regulations in Thailand can lead to a number of unwanted headaches for businesses. Firstly, there are the legal issues that non-compliant companies face. There is also the reputational risk that manufacturers found to have caused environmental harm may have to deal with. Reconciling both can take years to correct depending on the severity of the violation.

Moving towards a circular economy through co-processing

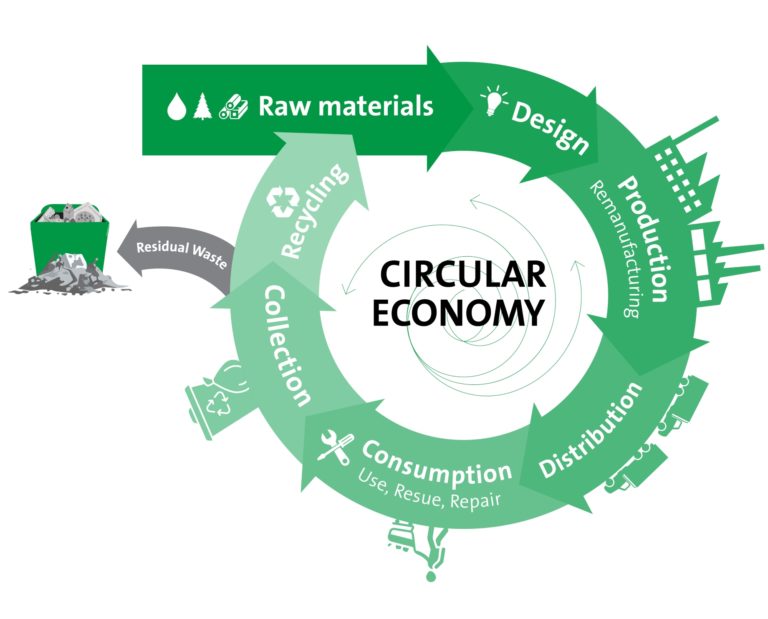

Thailand continues to move towards a circular economy, and this is something impacting industrial waste management. The Thai government has emphasized creating a circular economy in the Eastern Economic Corridor (EEC) as it looks to make business and investment in the special economic zone more environmentally friendly.

Since 2019, EEC officials have been cooperating with the United Nations Industrial Development Organisation to further implement circular economy principles within the EEC. Attention has focused on waste elimination along with recycling that sees resources reused.

Waste-to-energy continues to play a significant role in closing the loop of the circular economy in both the EEC and Thailand as a whole. Research from the DIW found that approximately two million tons of non-hazardous industrial waste was burned to produce energy in 2018. The country’s eastern provinces, including those that make up the EEC, are the ones leading the charge. Co-processing is proving to be a valuable tool in these efforts.

Co-processing sees waste used as fuel in cement kilns in place of fossil energy and virgin raw materials. The benefits of this are widespread. Cement plants receive a reliable local supply of fuel or material that replaces natural resources, businesses can dispose of their waste in an environmentally friendly method and communities benefit from a more ecological prudent solution.

When compared to traditional waste disposal methods such as landfilling or incineration, co-processing provides a number of advantages. To start with, the process completely destroys waste through high temperatures, oxygen excess and long residence time meaning there is nothing remaining.

Secondly, co-processing reduces greenhouse gas emissions since waste is used to replace fossil fuels. Lastly, it preserves natural resources. Companies needing to dispose of industrial waste can leverage co-processing to become zero waste organizations and help close the loop on the circular economy, especially in developing countries.

Take Thailand for example. Co-processing is needed here since recycling facilities are not yet available and many recycling technologies are financially not workable. Since it is classified as mineral recycling and energy recovery, co-processing can play a vital role in reaching the United Nations Sustainable Development Goals which provide the groundwork for a circular economy.

In particular, it will help Thailand move away from the ‘take, make, dispose’ model that leads to open burning, marine littering and disposal in uncontrolled dumpsites. Embracing co-processing ensures pressing need there is controlled disposal and energy recovery in the country while making an important and structural contribution to the improvement of waste management.

"Co-processing solution can contribute in the circular economy transition through Energy recovery from waste materials for which recycling facilities are not yet available or recycling technologies are financially not feasible"

Collaborating on industrial waste management with INSEE Ecocycle

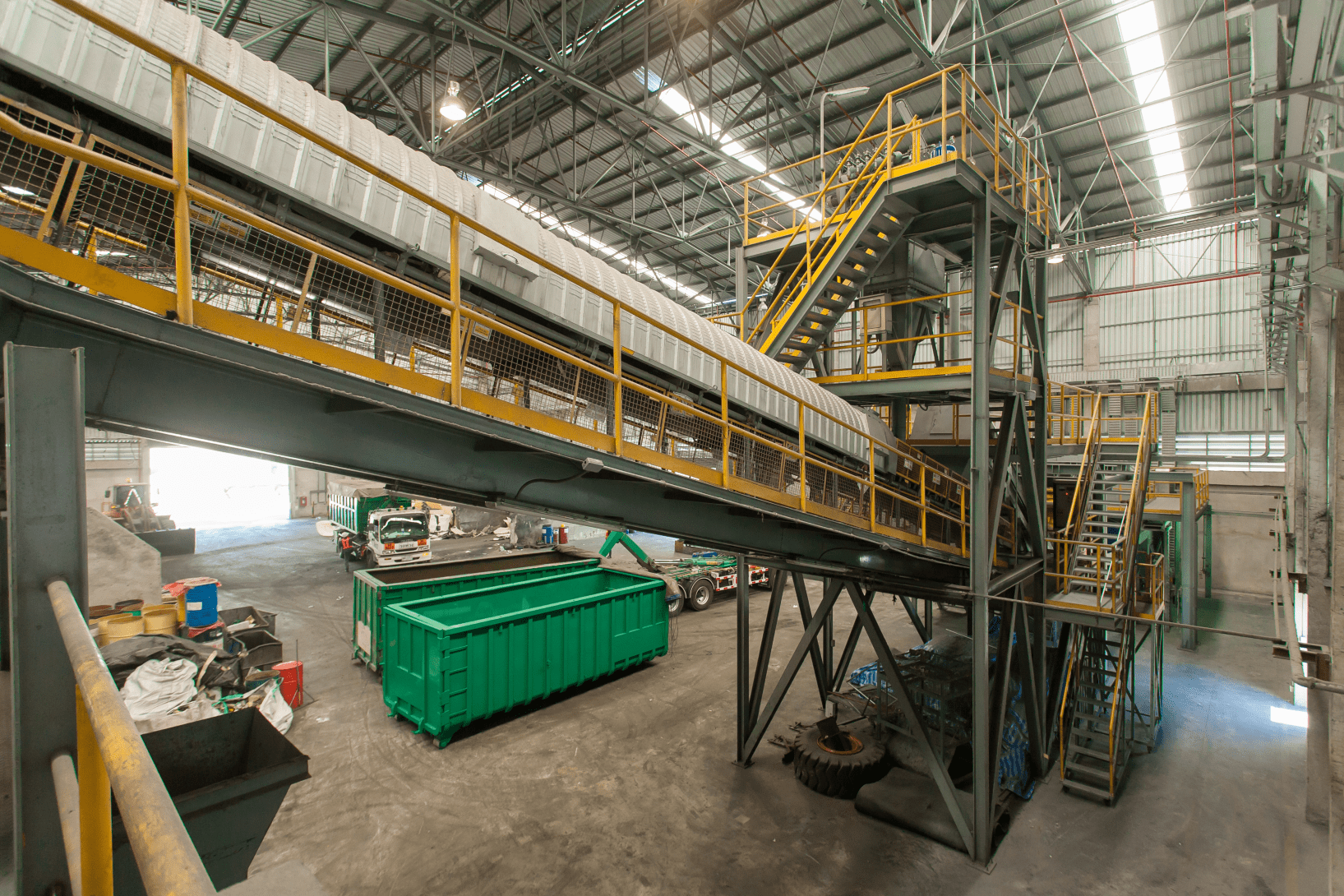

INSEE Ecocycle waste management services are inclusive of consulting, waste analysis, handling, logistics, processing and final treatment in the organization’s cement kilns. The process starts with collecting waste for pre-processing and ends with sustainable destruction in full compliance of all regulatory requirements.

The entire process is overseen by experts and specialists with total security in place throughout. All general regulatory requirements relating to waste as well as the additional regulations that apply to generating, storing, transporting, treating and disposing of hazardous and liquid wastes are strictly adhered to.

A collaborative partnership with INSEE Ecocycle empowers companies from various industries, including oil & gas; petrochemical; automotive; electronic & electric; fast-moving consumer goods and more, with total peace of mind that they are fulfilling their commitments to the circular economy.

If you want to ensure that all your waste is being handled by specialists who understand waste streams from your production process and know how to manage it under Thailand industrial waste management regulations, INSEE Ecocycle is the partner who can trust.

The reputation of INSEE Ecocycle is backed by numerous awards including being the first waste management company in Thailand to receive Green Industry Level 5 – Green Network. This is the highest rating in the entire green industry and reflects the strong commitment of INSEE Ecocycle when it comes to green activities with stakeholders along with supply chain.

Green Industry Level 5 highlights the organization’s goal of raising the industry standard and amplifying efforts throughout the service value chain. Partnerships with large reputation multinational companies and the adoption of the extended producer responsibility principle to take steps towards plastic pollution prevention are among INSEE Ecocycle’s most recognizable actions.