As the reality of climate change becomes increasingly apparent, we are all conscious that humanity is currently consuming resources at a rate beyond the level our planet can sustain in the long term. Although cement and concrete are, to date, among the lowest carbon-intensive building materials per unit of strength and per unit of cost, the concrete industry must play its part in continuously reducing the carbon intensity of the built environment.

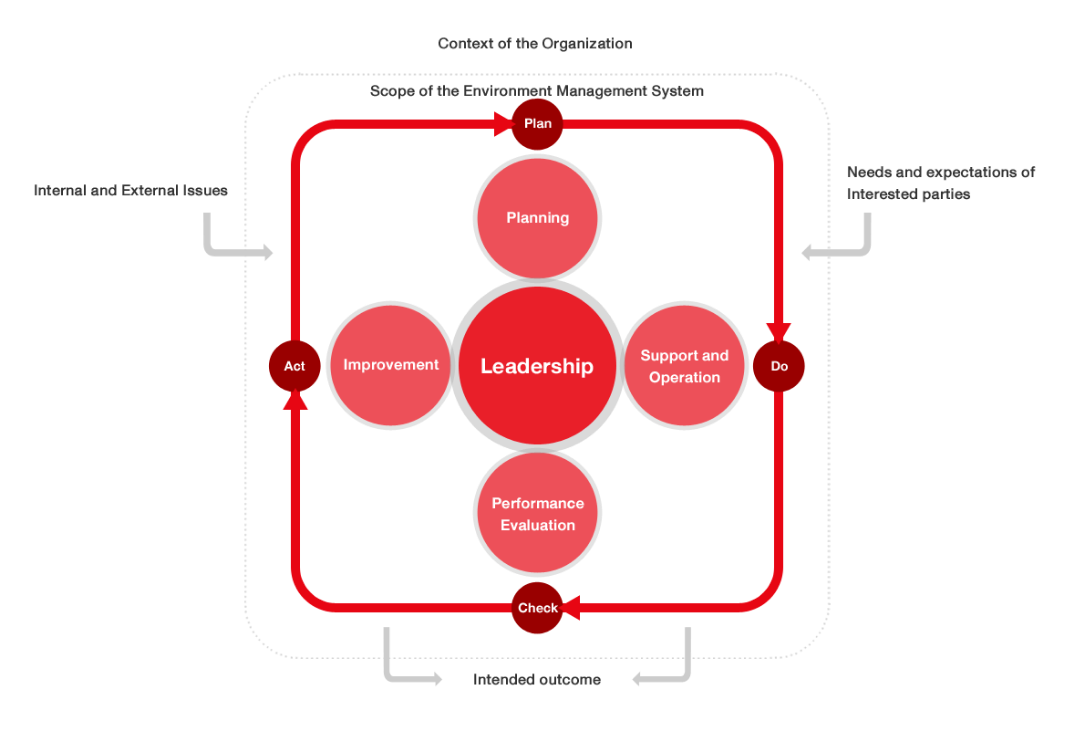

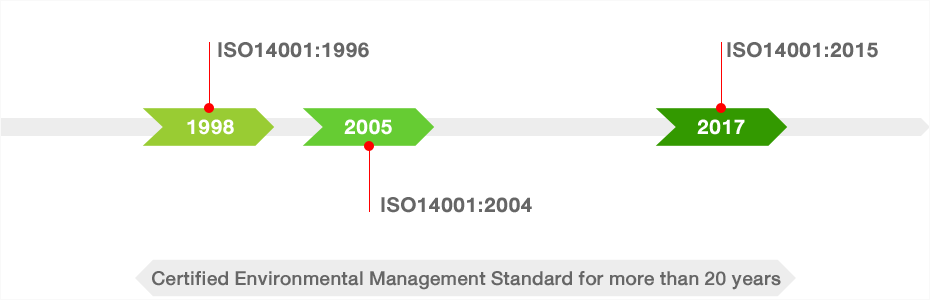

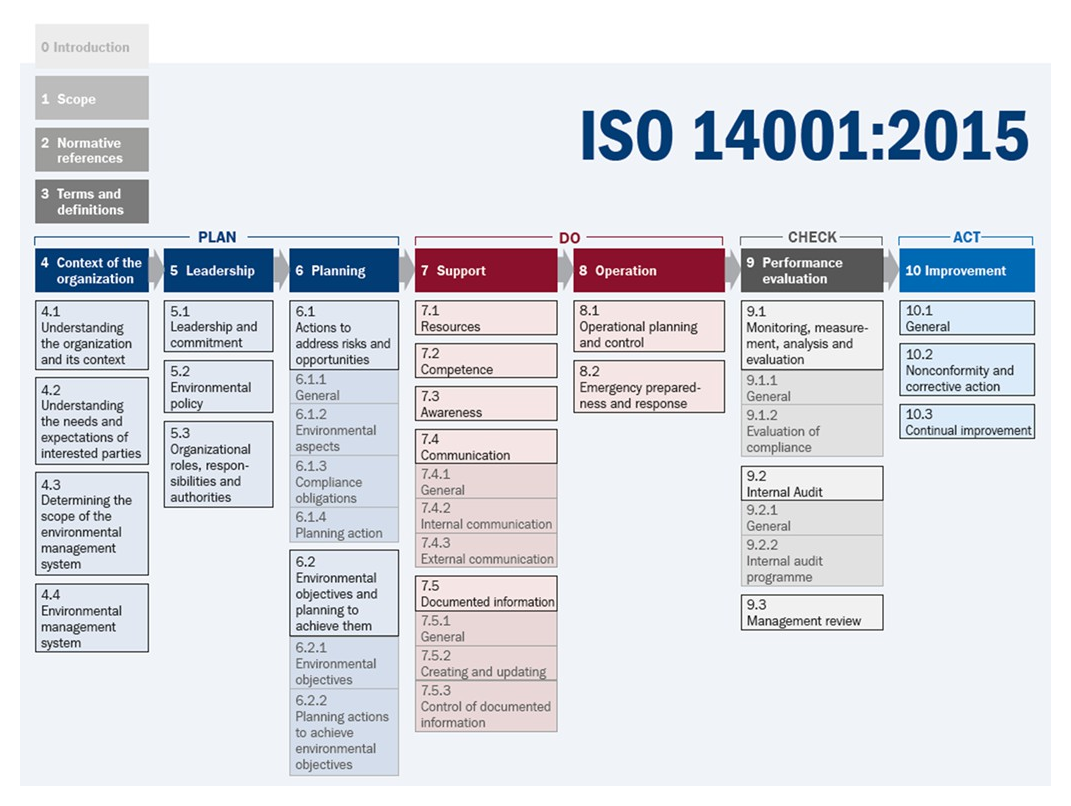

Maintaining the balance between productions and caring for the environment is an important element of our mission statement. To that end, Siam City Cement Public Company Limited has adopted the ISO14001: Environmental Management System as the organization’s guideline in the management of the environment.

Inspired by the promise of a more sustainable and prosperous future for all, SCCC Group has devised the Sustainability Ambition 2030 which the Thailand Cement Business supports. However, we develop our ambitious targets based on business operations in Thailand, in alignment with all business units across the Group, to ensure that the Company can make a positive impact on the environment as one.