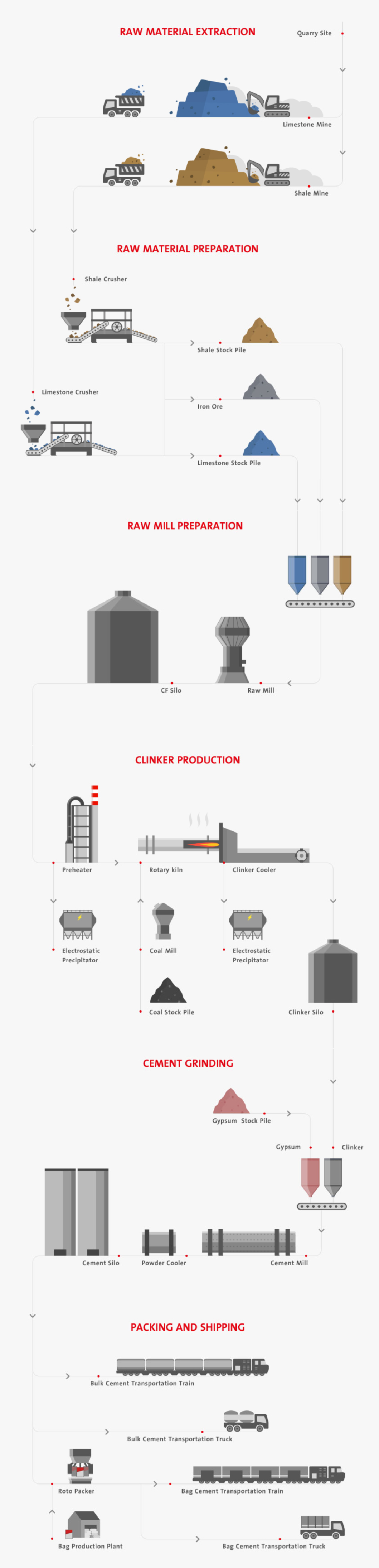

Ever wonder how our cement is made? Here is the production process that sees products go from quarry to consumer.

Production Process

MODERN TECHNOLOGY

Innovation drives our production process

MODERN

CEMENT KILNS

SCCC built kiln no. 5 in 1992 and kiln no. 6 in 1996, each with a daily clinker capacity of 10,000 tons. These remain among the most modern cement kilns in the world and have an excellent Overall Equipment Efficiency (OEE) when compared to other kilns in operation.

WASTE HEAT

RECOVERY SYSTEM

SCCC was the first cement manufacturer to recycle waste gas from the clinker cooler to generate electrical power. This process can produce up to 11 megawatts. The two main objectives of this system are:

-

To produce cost savings by using less energy

-

To reduce indirect CO2 emissions

This is a practical example of sustainable development in accordance with the concept of ISO 14001 system for continuous improvement.

SEPARATOR IMPROVEMENT

In order to improve production efficiency, our engineering team developed methods to replace the static separator with a dynamic separator. This resulted in an 15% production increase and a specific electric consumption reduction of 2-4 Kwh/t.

FUZZY LOGIC

CONTROL SYSTEM

Computerized systems support all production processes from line no.1 to 6. Using this technology ensures the quantity and quality are certifiable as defined by government identification.

LEARNING AND

DEVELOPMENT

SCCC offers everyone the opportunity to learn and develop their skills and knowledge as part of our Knowledge Management and Learning Organization. Employees learn from working and transferring experiences together. We provide a Technical Learning Center which uses IT systems to support Learning Anywhere and Anytime.