Why INSEE Ecocycle

INSEE ECOCYCLE – 18 YEARS JOURNEY OF SUSTAINABLE DEVELOPMENT AND CIRCULAR ECONOMY IN THE NET ZERO COMMITMENT

INSEE Ecocycle of INSEE Vietnam, one of the leading providers of waste management in Vietnam, is celebrating 18 years of our waste treatment journey. We have many great achievements, such as being the only unit in Vietnam licensed to handle PCB-contaminated oil. This is a hazardous waste that must be completely treated in Vietnam and globally by 2080. As a result, we are the 1st waste treatment unit in Vietnam to handle HCFC – the gas that causes global warming. INSEE Ecocycle has also thoroughly treated over 1,800,000 tons of hazardous and non-hazardous waste, fully complying with Vietnam's environmental protection laws as well as the Group's standard regulations. This result is equivalent to reducing more than 1,700,000 tons of greenhouse gas emissions into the environment. As a long-term investor in Vietnam, the environment is one of our core values. We always reaffirm our commitment to reducing emissions and achieving "Net Zero" in each climate change action to reduce carbon emissions to zero by 2050.

OUR CUSTOMER VALUE

KNOWLEDGE AND SKILLS IN BUILDING THE MOST SUITABLE SOLUTION FOR OUR CUSTOMER’S REQUIREMENTS.

Experience in waste treatment for various well-known companies in a wide range of manufacturing industries.

INSEE Ecocycle Vietnam has been processing more than 100,000 tons of waste per year in order to accompany customers in preserving our environment and enhancing sustainable development by managing waste effectively, which helps to gain credibility and create competitive advantages.

Treating waste for customers using the technology of co-processing waste in cement kilns, which has been accredited for safety and environmentally friendly performance that is superior compared to incineration or landfilling by:

- Extremely high temperatures - up to 2,000°C, oxygen excess, and long residence time destroy waste materials completely.

- 24/24 Emission control system in every INSEE Ecocycle plant ensures emission safety according to Siam City Cement Group’s global standards.

- No residue after the process, so customers do not have to concern about related legal responsibilities or reputational risks. Moreover, co-processing helps reduce the waste going to landfill than if treated by other technologies.

- Capability to collect and treat a wide range of waste in mass volumes greater than 700 tons/day. Customers totally trust our waste treatment service in cases of expanding businesses and increasing waste volume.

- Co-processing waste will not generate more CO2, leading to improved environmental protection performance and social responsibility for customers.

Protecting brand value and credibility for customers because INSEE Ecocycle complies with all legal regulations, applies the highest standard regarding safety and environment protection while operating.

- ISO 9001 Quality Management System in 2015

- ISO 50001 Energy Management System in 2011

- OHSAS 45001 Occupational Health and Safety Management System in 2018

- Supplier Ethical Data Exchange SEDEX – promote business ethics and social responsibilities in global supply chain

- Internal Risk Management assurance methodology (ECO-Assessment)

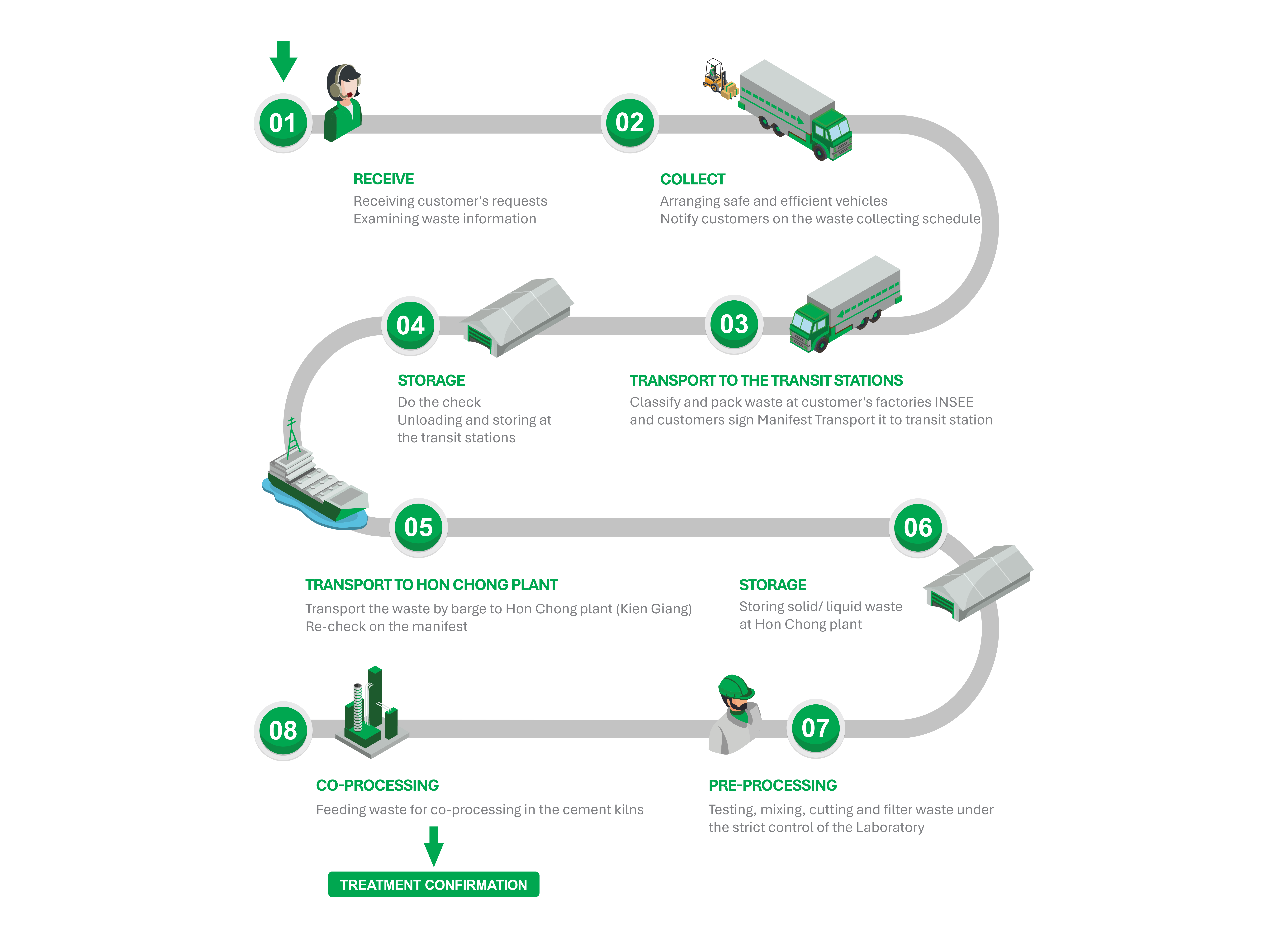

INSEE Ecocycle members will cooperate with customers to design customized total waste treatment solutions, from waste analysis to complete disposal, appropriate to the particular waste conditions of customers.

- Consult on effective waste treatment: Ensures customers waste treatment complies with legal regulations & Consults the waste treatment solution to ensure safety and health operations at the customer’s site.

- Analyze waste using advanced technology equipment: Provide the safest solutions for handling, mixing, packaging, storing, logistics & Bring forward a safe solution for waste pickup and transportation.

- Waste transportation by well-trained and well-equipped supervisors and drivers The waste material is collected and transported to be treated in rotary cement & Customers may supervise the transport waste with GPS equipment for real-time itinerary tracking.

- Pre-processing at INSEE Ecocycle plants by well-experienced employees and automatic and modern facilities: Waste material is pre-processed at the plant to minimize waste exposure to humans.

- Co-processing in cement kilns: Leaving zero residues that need to be landfilled after processing and excluding risks that have an impact on the company’s credentials compared to decomposition or landfilling, INSEE Ecocycle provides the best solution for waste treatment for the environment and social community.