WASTE MANAGEMENT

INSEE ECOCYCLE VIETNAM WITH THE ‘CO-PROCESSING IN CEMENT KILNS’ TECHNOLOGY

INSEE Ecocycle is a subsidiary of Siam City Cement Group, with 18 years of experience in providing safe and environmentally friendly waste management solutions in Vietnam. Established in 2007, INSEE Ecocycle is proud to be a leading and a trustworthy partner in Vietnam through the technology of co-processing in cement kiln.

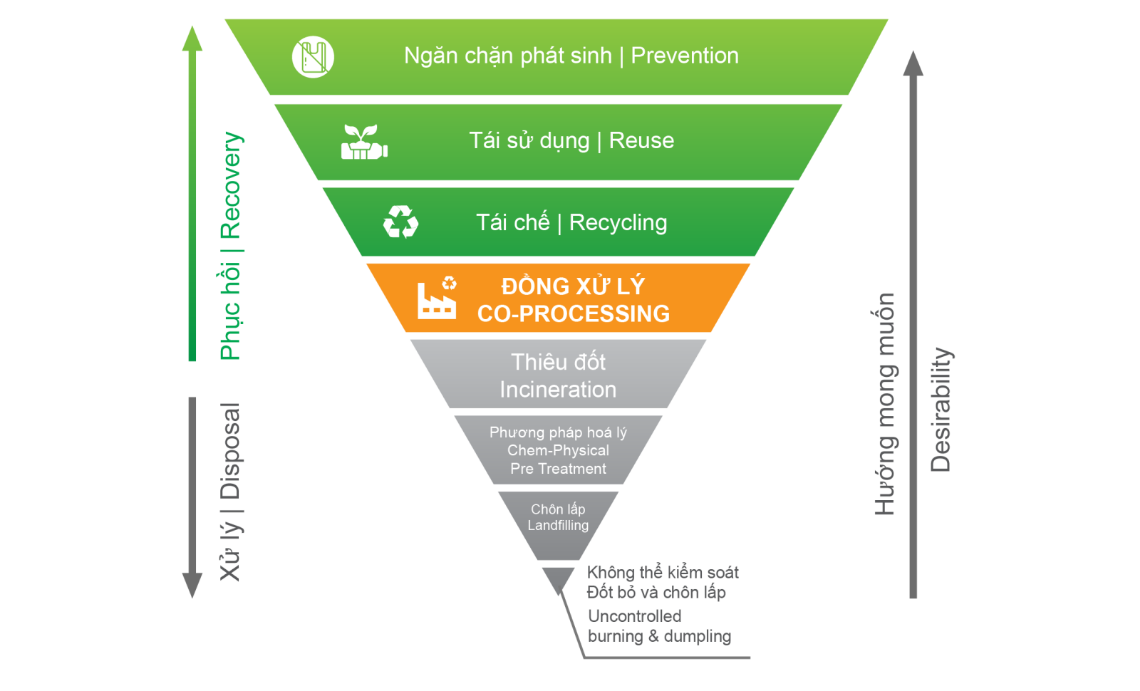

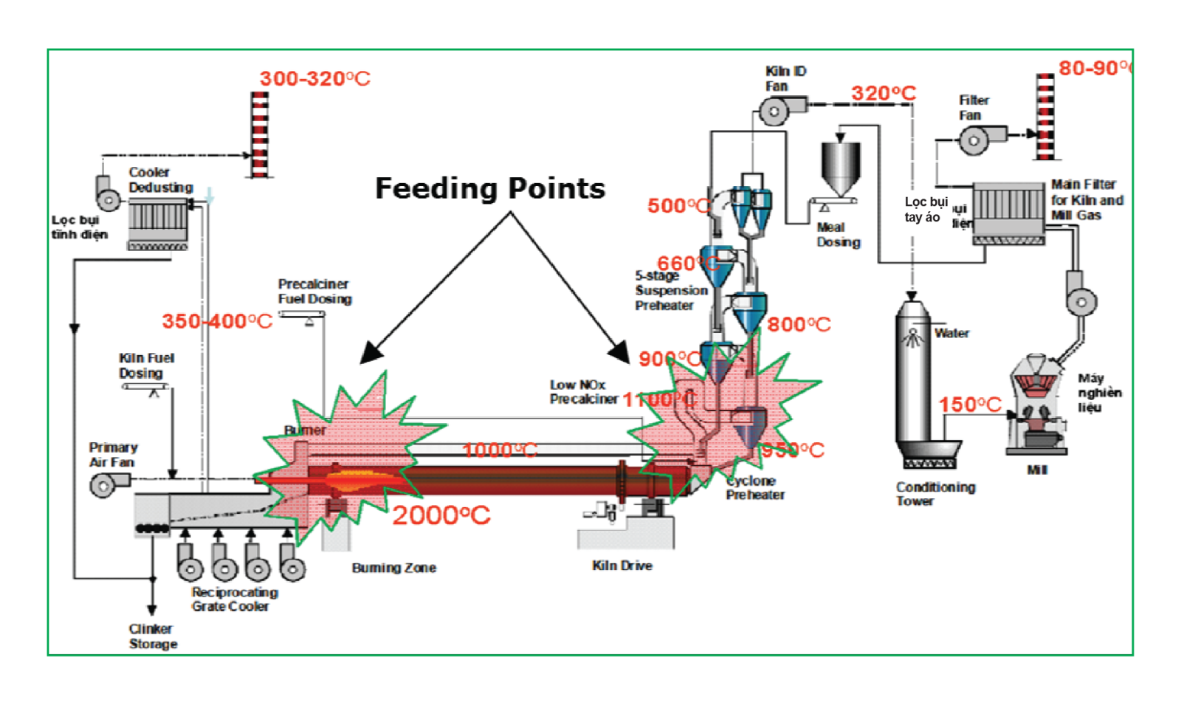

We use co-processing technology with inherent process properties such as extremely high temperatures (gases reach up to 2,000 Celcius), a long residence time, and an alkaline environment. A key advantage we have: all waste is fully destroyed. The thermal energy is recovered, and the minerals are incorporated into the clinker matrix.

Therefore, there are no by-products generated, that reducing the carbon footprint of cement plants while also leaving no ash residue. The co-processing is highly efficient and safe for a wide variety of wastes, such as:

- Hazardous waste: solvents, sludge, pesticides, etc.

- Non-hazardous waste: copper slag, footwear, apparel, plastic, FMCG, cosmetics destroyed, discarded products, ash, nix, etc.

ADVANTAGES OF OUR TECHNOLOGY

- High & stable temperature (up to ~ 2000 °C)

- Long residence time (gas ~ 8 sec, solids 30min)

- Alkaline environment and self-cleaning process (CaO)

- Large capacity (30 tons of waste/hour)

- Continuous emission real-time monitoring 24/7

- C02 emission reduction

- No ash residue, all materials retained in clinker

- Sustainable development technology

A key advantage we have: all waste is fully destroyed. The thermal energy is recovered, and the minerals are incorporated into the clinker matrix. Therefore, there are no by-products generated, reducing the carbon footprint of cement plants while also leaving no ash residue. The co-processing is highly efficient and safe for a wide variety of hazardous and non-hazardous waste.

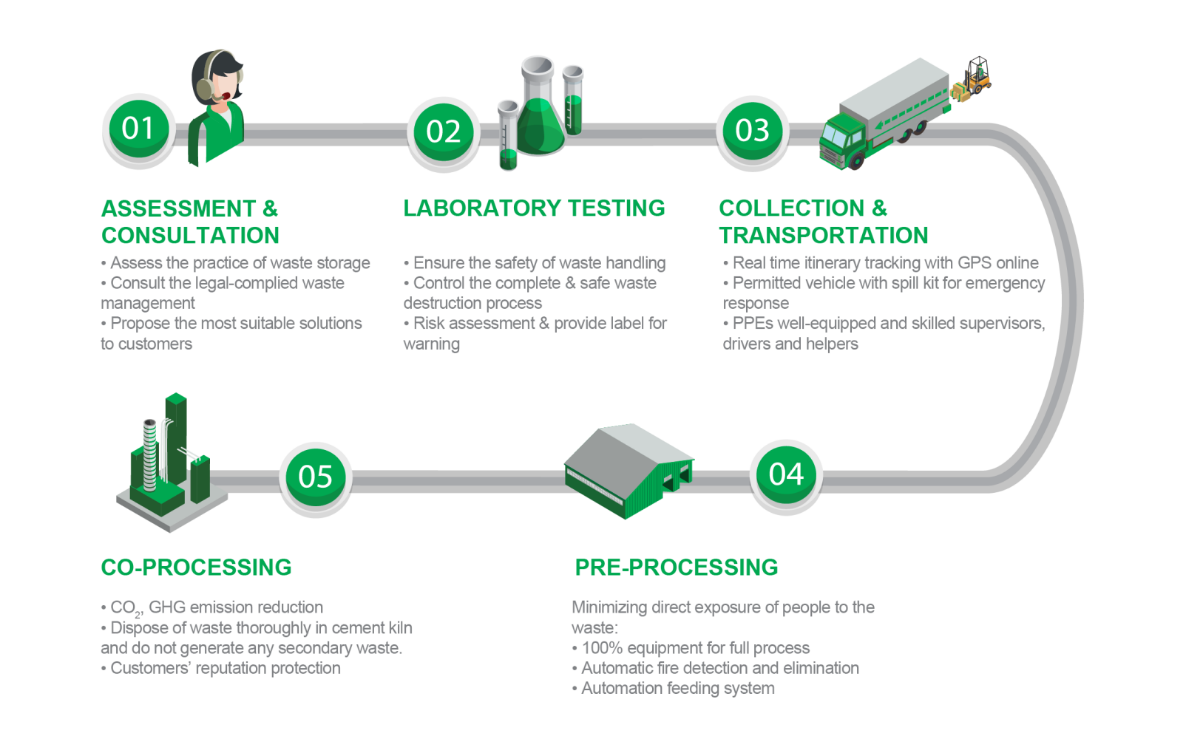

PROCESS OF NON-HAZARDOUS AND HAZARDOUS WASTE MANAGEMENT OF INSEE ECOCYCLE VIETNAM