OUR PRODUCTION PROCESS INVOLVES CAUTIOUS STEPS FROM TRANSFORMING RAW MATERIAL TO FINISHING THE PRODUCT, AND BE READY TO DELIVER VALUE TO OUR CUSTOMERS.

Production Process

MODERN TECHNOLOGY

MODERN TECHNOLOGY FOR EXCELLENT QUALITY

HOW CEMENT IS PRODUCED

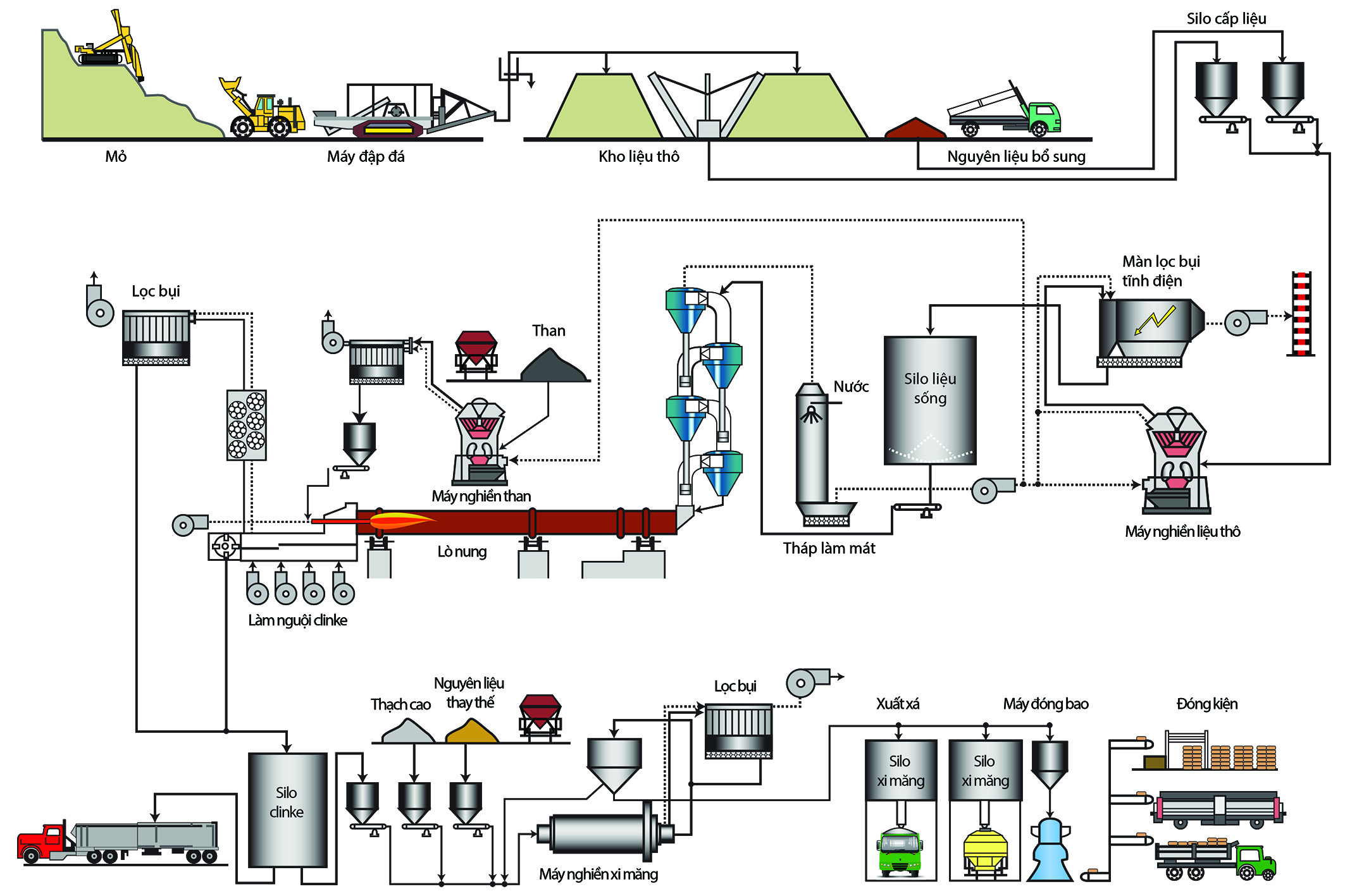

Cement is produced from raw materials such as limestone, clay, and sand. These raw materials are quarried, crushed, ground-granulated, blast-furnaced and blended to the correct chemical composition. Small quantities of iron ore, alumina, and other minerals may be added to adjust the raw material composition. Typically, the fine raw material is fed into a large rotary kiln (cylindrical furnace), where it is heated to about 1,450°C with material temperature, gas temperature up to 2,000°C. The high temperature helps the raw materials to react and form a hard-nodular material called “clinker.” The clinker is then cooled and ground with gypsum and other additives to produce cement.

Vertical Roller Mills (VRM)

Cement grinding mills are the second-highest energy consumer at the plant. At INSEE, we are proud to operate Vertical Roller Mills (VRM), which require more competent maintenance from mill operators, from material preparation to quality control.

Waste-heat recovery power plant

State-of-the-art new suspension process (NSP) kilns include multi-stage pre-heaters and pre-calciners to pre-process raw materials before they enter the kiln and an air-quench system to cool the clinker product. Kiln exhaust streams, from the clinker cooler and the kiln pre-heater system, contain useful thermal energy that INSEE can convert into power. Optimizing furnace technology performance is important for efficient plant operation, utilizing exhaust heat from the preheater tower and clinker cooling system to generate electrical energy to partially compensate for electrical energy that must be purchased from the national grid. Waste heat recovery power plants bring great benefits to the economy, society, and environment, meeting 25% of the power demand of the plant, equivalent to the amount of electricity for 18,000 households in 1 year. The power plant with a capacity of 6 MW reduces the burden on the national grid and helps INSEE indirectly save about 25,000 tons of carbon emissions in a year, equivalent to 9,300 tons of coal.

.jpg)

Bag filters to reduce dust emissions

At Hon Chong plant – Kien Giang, we have installed one of the most modern cement manufacturing lines. According to the needs of production and business, we continue to invest in upgrading this line, especially the electrostatic precipitator system – dust removal for furnace flue gas - has been replaced with a more sustainable solution: dust bag filter system.

This investment is a recognition of our sustainability efforts. The bag filter system was successfully implemented in March 2013, a step forward in the development of Hon Chong Factory towards the goal of improving Environmental Indicators. Dust emission at the main chimney of the clinker kiln of Hon Chong Plant is less than 10 mg/Nm3; well below the limit required by Vietnamese law of 100 mg/Nm3 (QCVN 41:2011).