INSEE Dang

Mixed Cement For Quality Bricklaying And Plastering Works

INSEE Dang is mixed cement, manufactured from Portland cement clinker finely ground with other inert materials which produces a mortar of high plasticity.

Its specification conforms to the Thai Industrial Standard for Mixed Cement TIS 80-2566.

Cement Qualification

INSEE Dang is suitable for masonry and plastering works where minimal mortar shrinkage and smooth finishing are required. The INSEE dang is also suitable for ordinaryconcrete works such as general housing works, concrete pavement, concrete tiles, piers, drain pipes, septic tanks, water tanks, etc.

Recommendations

- Clean the surface before plastering for better adhesion.

- Moisten the wall before plastering to avoid cracks from rapid water absorption.

- Do not directly expose the just finished plastered wall to sunlight to avoid cracks from heat and rapid water loss

- For plastering works, curing is highly recommended especially 1-3 days after plastered (in this period plastered walls should be kept damp) in order to avoid cracks and to help concrete to develop itscompressive strength.

- Keep the cement under shade and cool-dry area.

- Do not store cement for more than 2 months and once opened should be finished within 1-2 day

Mixing Proportion

Mix the volumetric proportion of INSEE Dang, rock gravel, sand and water as follow;

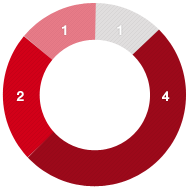

General Structure

INSEE Dang : 1

Sand : 2

Rock : 4

Water : 1

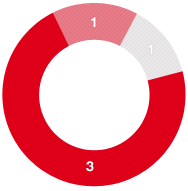

Bricklaying works

INSEE Dang : 1

Sand: 3

Rock : -

Water : 1

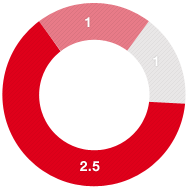

Internal plastering works

INSEE Dang : 1

Sand : 2.5

Rock : -

Water : 1

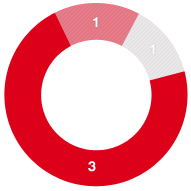

External plastering works

INSEE Dang : 1

Sand : 3

Rock : -

Water : 1

Remark: Coarse sand is used for concrete and bricklaying works. Fine sand is used for plastering works.

Mix proportion can slightly adjust to follow the condition at jobsite

Packaging

- Bag Cement 50 kg

Technical Specification

| Physical Qualifications | TIS. 80-2566 | INSEE Dang |

|---|---|---|

| 1. Blaine Air Permeability

(sq.m./kg.)

|

> 320

|

535

|

| 2. Setting Time (Vicat Method)

Initial (minutes)

Final (minutes)

|

> 45

-

|

97

-

|

| 3. Mortar Compressive Strength

1 days (MPa)

3 days (MPa)

7 days (MPa)

|

-

> 6.9

< 11.8

|

6.2

11.5

13.8

|